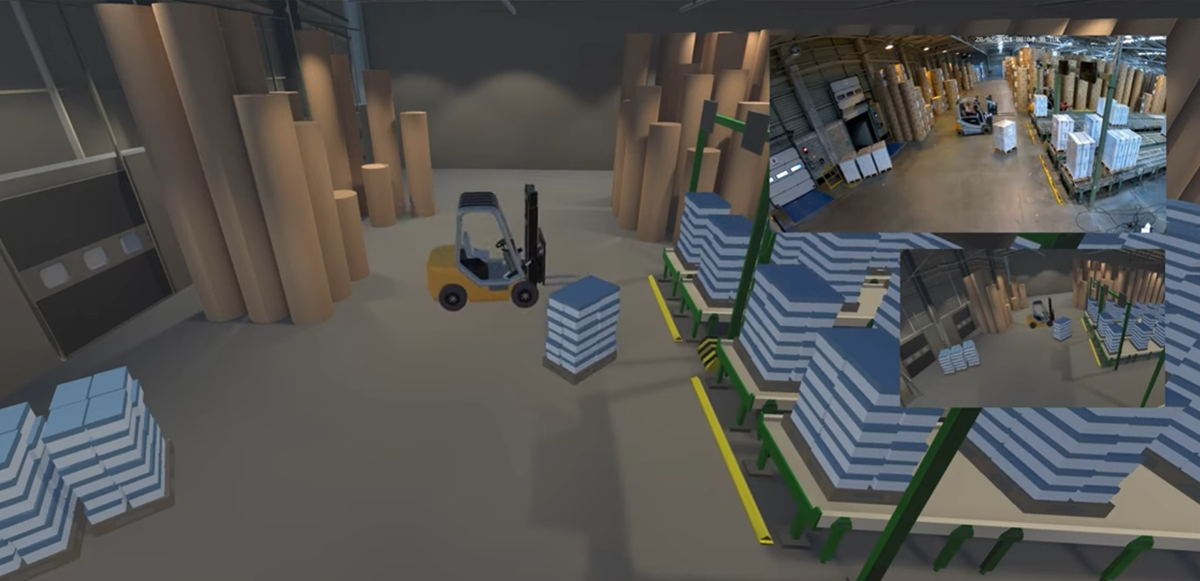

Infinite Foundry was founded in Porto to apply advanced digital technologies, particularly digital twins and physics-based artificial intelligence, to the industrial sector. Today, it is a benchmark in the market and has expanded its activities beyond process traceability and anomaly detection to include industrial process optimisation, virtual training, and the orchestration of fixed and mobile robotics.

In the automotive industry, digital twins have a significant impact by reducing development times, improving the quality of the final product, anticipating production faults and significantly increasing operational efficiency. The Digital Twin consists of an exact and dynamic virtual replica of a physical system, enabling continuous real-time monitoring, analysis and optimisation.

Infinite Foundry stands out from the competition in the market through the advanced integration of real-time 3D digital twins with physics-based artificial intelligence (virtual sensors). This combination makes it possible to understand industrial operations in detail, accurately predict failures and continuously optimise, constituting an integrated solution that is more robust and effective than traditional stand-alone technologies.

Read the full article.